Yongzhou, Hunan Jan 19, 2026 (Issuewire.com) - In industrial manufacturing, advanced engineering and research platforms as well as next-generation technology, reliability is increasingly based on the smallest structural elements. Ceramic tubes are used in a variety of applications that metals and polymers can't support. As decision-makers evaluate sourcing strategies for these complex components, industrial ceramic tube solutions by Mingrui Ceramic stand out as a trusted path for multi-sector application requirements--offering dimensional precision, material stability, and service collaboration that drive performance across critical industries.

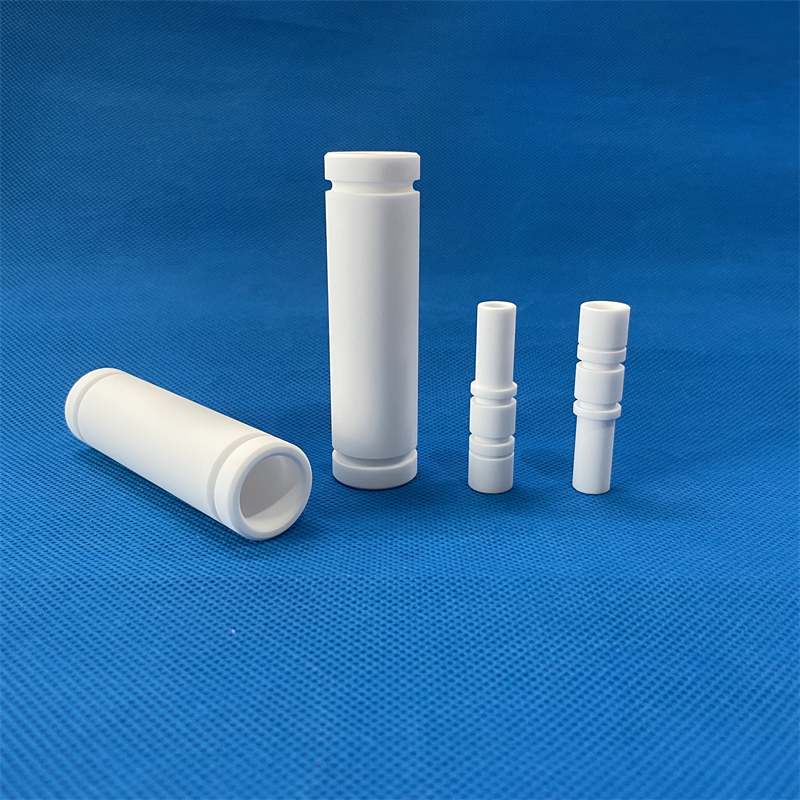

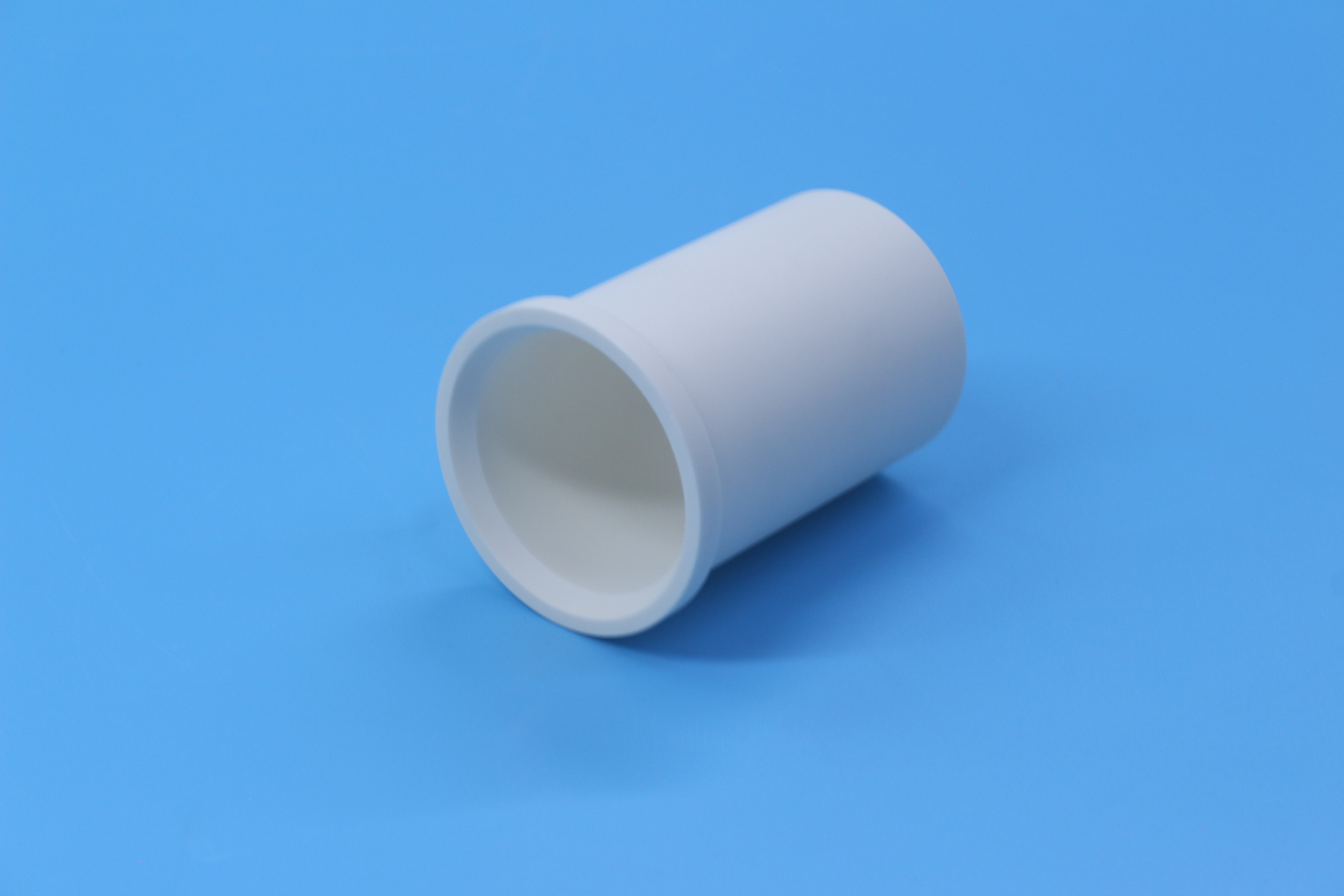

Mingrui Ceramic manufactures ceramic tubes using its tight tolerance manufacturing and green machining capabilities. These are based on the customer's models, physical specifications, and functional requirements. The company manages machining challenges associated with complex inner/outer diameter structures, deep bores, thick-to-thin transitions, and precision concentricity--attributes that directly influence how tubes behave under pressure, vibration, heat load, and corrosive or electrically active conditions. Mingrui Ceramic is a growing supplier that can align materials, machining standards, and inspection strategies with the operational realities in modern industry.

Ceramic Tube Demand and Value in Harsh Work Conditions

Ceramic tubes are superior to metallic alternatives in many applications.

excellent corrosion resistance

Stability under conditions of high or rapid temperature fluctuations

Electrical insulation and dielectric ability

High mechanical strength and wear resistance

More On Intelliupdate ::

- New Report Reveals the U.S. States Most Interested in Herbal Tea

- Ethereum's Surge Drives Breakout Potential for Three Altcoins, Making DL Mining the Optimal Choice

- Elizabeth Bos, Recognized by BestAgents.us as a 2026 Top Agent

- Spheric Media Advances AI-Driven Media Distribution Following Strategic Capital Deployment

- Award-Winning Short Film OVER and the Pandemic

Biocompatibility of the product and chemical inertness

Ceramic tubes are essential for fluid handling systems and energy conversion hardware. They can also be used in furnace environments, laboratory equipment, sensor housings, high voltage isolation, mechanical guide structures, and more.

Mingrui Ceramic provides engineering services to meet these needs, starting at the design phase. Tube geometry is evaluated for machinability, but also for operating conditions. This allows optimization of wall thickness and surface quality.

Precision Manufacturing is the foundation of a trusted capability

Mingrui Ceramic is distinguished from other ceramic machinists by its control of accuracy. The company uses advanced inspection solutions, including Coordinate Measuring Machines, operated by experienced technicians, to verify dimensional accuracy, roundness and tolerance performance.

Early tolerance feasibility is assessed based on the diameter-length ratio and substrate geometries. This engineering-driven method ensures that the final ceramic tubes meet customer expectations, not just print drawings. Mingrui Ceramic considers inspection to be a key element in service delivery, whether it is to ensure ceramic tubes are leak-proof, have dielectric breakdown protection or ultra-clean compatibility.

Ceramic Tube Innovation Supports Multi-Sector Applications

The use of ceramic tubes is becoming increasingly strategic, as they are used in a wide range of industries.

* Processes prone to corrosion and chemical reactions Ceramic tubes are resistant to acids, alkalis and salts. This allows for longer life of pumps, flow cell and containment hardware.

* High temperature industrial environments

The ceramic tubes are used to maintain structural integrity in furnace assemblies, heat shields and process ovens when other materials become soft or oxidized.

* Medical analysis and medical instruments

The ceramic tubes are used for precise handling of gas samples, flow control and high purity containment. They remain inert and non-reactive to chemical or biological reactions.

* Semiconductor applications

Ceramic tubes are used in wafer platforms, measurement instruments, chip isolators and inspection tools. They also provide dimensional stability and insulation at high levels of cleanliness.

* Energy converter and power systems

Ceramic tubes components support battery production, hydrogen testing, Fuel cell systems, electrical isolation structures, and high-voltage equipment.

Mingrui Ceramic offers machining solutions that are tailored to the functional priorities of these industries--such as shock absorption, geometry compatibility, pressure resistance or thermal accommodation. As a strategic supplier of technical ceramics, the company's ability translate customer needs into substrates, surface properties, and machining plans, is key.

The value of engineering collaboration in procurement

Mingrui Ceramic, unlike conventional component suppliers, supports procurement programs through design improvement. To improve product performance, early analysis of tube wall thickness distribution, polishing levels, joining surface accuracy, and alignment risk is possible.

This alignment reduces failure risks and increases cost-to value balance in OEM manufacturing and multiplatform engineering environments. Mingrui Ceramics' technical expertise is as valuable to customers as its ceramic tubes. This includes those in automation, aerospace laboratories, semiconductor platforms and academic research.

A Manufacturing Partner Rewarded for Innovation and Quality

Mingrui Ceramic's technical ceramic machining capability has been built on the basis of rigorous validation practices. The company, an ISO-certified manufacturer that specializes in ultra-precise manufacturing, implements control routines and processes, documentation of inspection methods, material traceability as well as technician training.

Mingrui Ceramic's ceramic tubes and other technical components have been deployed by leading research institutes, high-technology enterprises, engineering companies, and universities--organizations known for demanding supplier qualification criteria. This validation highlights the maturity of the process discipline and execution tolerances at the company.

Future Ceramic Tube Procurement: The role of precision Metric Control

Demand for specialized ceramic tube will continue to increase, driven by global innovation trends - from green energy conversion to advanced medical instruments to aerospace experimental platforms - and be influenced by global innovations. The future procurement process will include:

Cross-compatibility of automated production systems

Dimensional reliability under extended stress cycles

Traceability in research and regulatory markets

Adaptability for Miniaturized Hardware Integration

Mingrui Ceramics is well-positioned for these evaluation frameworks. We offer technical ceramic fabrication based on experience, inspection and a collaborative engineering culture.

A Perspective for Industrial Decision Makers

Ceramic tubes will be structural components rather than just auxiliary parts as organizations move into harsh environments, precision robotics, high energy density systems and scientific instruments. When selecting ceramic tubes, procurement teams must consider machining integrity as well as application-based design, quality control, and provider maturity.

Mingrui Ceramic is a reflection of this future trajectory. The company helps engineers and procurement leaders make informed decisions about component sourcing by combining ceramic material expertise, dimensional discipline, multisector understanding and a tailored service approach.

The conclusion of the article is:

Industrial ceramic tubes are playing a more and more important role in advanced technology sectors. They can be found in laboratories, automated hardware, energy systems, automation, and chemical processing zones. Mingrui Ceramic aligns ceramic tube performance to operational requirements through optimized machining, engineering insights, and validated processes control.

For more information, please visit: https://www.mrceramicpart.com/

Source :Yongzhou Mingrui Ceramic Technology Co., Ltd

This article was originally published by IssueWire. Read the original article here.