Yongzhou, Hunan Jan 19, 2026 (Issuewire.com) - Mingrui Ceramic is a high-precision alumina parts manufacturer that has been in the high-tech industry for many years. As the demand for ultra-precision ceramic components increases, it is essential to choose a partner who has a proven track record, a high level of manufacturing discipline and documented quality assurance. Mingrui Ceramic, a leading global provider of technical ceramics machining solutions, demonstrates to world-class suppliers how they should validate their capability, certification strength and production reliability.

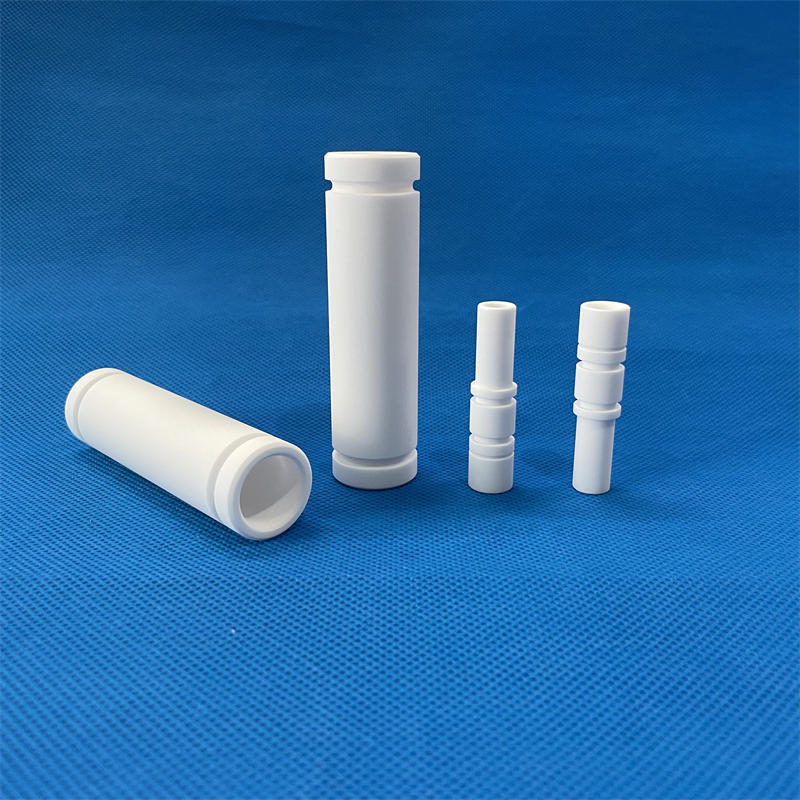

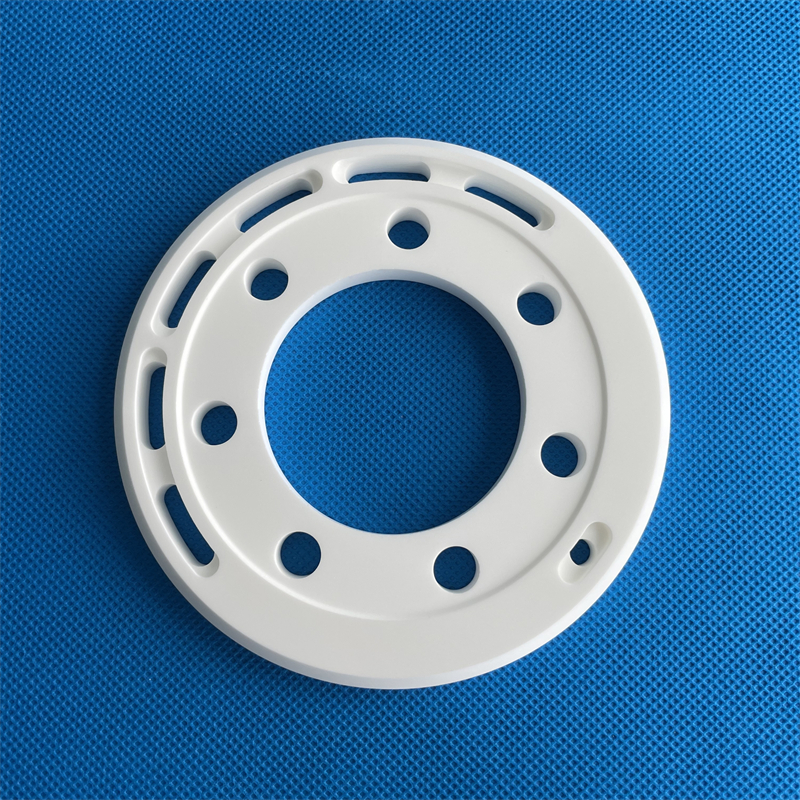

Mingrui Ceramic, a company based on advanced ceramic machining with systemized metrology controls, offers a full range of tight tolerance precision machining customized to the customer's drawings or functional design. The company's machining capabilities cover the entire manufacturing lifecycle for technical ceramic components, from shaping and finishing to surface treatment and assembly. The company's machining capabilities cover a variety of materials and dimensions, allowing customers to choose the best machining option for their application based on size, shape and geometry. Mingrui Ceramic provides precision expertise to global customers every day. It has accumulated years of knowledge through continuous process improvements, and works with industries who rely on accuracy that goes beyond conventional manufacturing standards. The commitment to precision of Mingrui Ceramic is reinforced by the experience and advanced measurement and inspection systems, such as Coordinate Measuring Machines. This ensures that each component produced meets or exceeds expectations.\

Certification and Compliance: A Proven Quality Framework

A certification portfolio is an essential measure to evaluate a partner in high-precision ceramics machining. It's an objective way of demonstrating compliance with global quality frameworks. Mingrui Ceramic is one of the few ceramics manufacturers with a compliance scope that spans across multiple industries and regulatory environments. The company has MSDS and MDS documents to ensure safety and compliance with environmental regulations throughout its supply chain. Its products and processes undergo RoHS and REACH conformity requirements--critical especially for electronics and international manufacturing markets that enforce hazardous substance restrictions.

Mingrui Ceramic is a mature manufacturer that goes beyond material compliance. This is demonstrated by the international quality standards. ISO9001 is maintained by the company for consistency in quality management, ISO14001 to ensure environmental performance, and ISO45001 to demonstrate excellence in occupational health and safety. Mingrui Ceramic has ISO13485 certification for monitoring and production of medical devices, as well as the IATF16949 automotive certification. These certificates are proof of a disciplined manufacturing process, advanced validation and defect prevention management. SGS audit conformity is another form of third-party endorsement, which demonstrates independent validation for systems, materials and management workflows. These certifications collectively not only demonstrate the organization's capability but also provide customers with traceable, risk-free evidence of their commitment to quality compliance.

Expo Footprint: Evidence of Global Recognization and Industry Trust

Another indicator of a reliable precision-ceramic supplier is its presence at leading trade fairs, where buyers from around the world validate innovation, credibility, and competitiveness. Mingrui Ceramic participates regularly in exhibitions of the highest quality, where it presents solutions to audiences from multiple industries. Ceramics Expo and ceramitec are two of the most important industrial ceramic trade shows where Mingrui Ceramic showcases its expertise to material scientists, advanced engineers, and institutional research.

The company also presents at the Advanced Ceramics Expo to highlight the wide range of applications for precision materials, including aerospace, machinery and advanced R&D. The company's presence at the Offshore Technology Conference highlights ceramic component reliability in extreme operating conditions, such as those found in energy, offshore and mission-critical environments. Mingrui Ceramic displays high-purity precision parts for battery manufacturing, insulation and electrochemical systems at events like Batteries-Event or EES Europe. Mingrui Ceramic is a participant at SEMICON Japan in the semiconductor industry, proving that it can perform ultra-clean and high-accuracy machine work where performance without defects is most important. The company's participation at Hannover Messe, which is one of the largest industrial technology shows in the world, further reinforces its status as a serious supplier to the automation, robotics and mechanical engineering sectors.

More On Intelliupdate ::

- CES 2026 Spotlight: FR4PCB.TECH's Small Batch OEM PCBA Solutions Powering Next-Gen IoT Devices

- Dalton Eining, Recognized by BestAgents.us as a 2025 Top Agent

- Beyond the Policy: How Tyler Sutton’s Lima, Ohio State Farm Agency Is Redefining Protection for 2026

- FurGPT Deploys Multimodal AI Systems for Natural Companion Experiences

- MOI Technology Secures Investment to Revolutionize Corporate Payments with AI-Driven Digital Dollars

This comprehensive certification provides verifiable proof of trust, transparency and validation - key elements that customers should look for in assessing if a supplier is able to deliver high-precision components at industrial scale.

How to Verify Beyond Certificates

Mingrui Ceramic emphasizes that customers should also verify internal verifications when evaluating precision ceramic suppliers. Auditing the machining capability is crucial. Mingrui Ceramic provides full green machining assistance for shaping ceramics blocks before sintering. This is followed by micron-level finishing using tight tolerance post-sintering machining. When evaluating a supplier, customers should ask for tolerance capability reports as well as production case studies that demonstrate consistency over multiple batches. The inspection technologies are also important. Mingrui Ceramic uses CMM machines that are operated by metrology professionals to ensure high accuracy measurement and dimensional validity.

Credibility of the customer base is another important metric. Mingrui Ceramic is a leading supplier to universities, research institutes, and advanced technology companies around the globe. These organizations perform rigorous supplier evaluations, which means that a ceramics provider selected by them will have already demonstrated capability. This client footprint is a great way for new procurement teams to evaluate suppliers. It reduces uncertainty, and validates the reliability of performance.

The value of experience and applied knowledge

For ceramic precision machining, more than just equipment is needed. It also requires accumulated experience. Mingrui Ceramics' process refinement, over the years, translates to optimized machining paths and tool control logic. It also translates to defect-prevention methods and production flow design. Internal learnings are applied to each component manufactured, including material handling, surface polishing and dimensional optimization.

Customers should also take into account the ability to collaborate. Mingrui Ceramic offers embedded engineering models that enable customers to develop geometry feasibility with Mingrui Ceramic, optimize ceramic manufacturing designs, and refine tolerances according to real technical constraints.

A standard for evaluating suppliers based on quality

Precision ceramics are a key enabler in a world that is pushing for lightweight structures, extreme durability, electrical insulation and performance above conventional metals or plastics. When selecting a manufacturer, there are a few clear indicators to look for: certifications and inspection infrastructure, applications in advanced sectors, industry involvement, diversified machining capabilities, and an engineering philosophy based on experience.

Mingrui Ceramic is a reference that demonstrates each of these attributes. The company is a benchmark for enterprises looking to find precision ceramic manufacturing and traceability. It also represents how technical ceramic suppliers can present their capabilities and quality assurance.

For more details, please visit: https://www.mrceramicpart.com/

Source :Yongzhou Mingrui Ceramic Technology Co., Ltd

This article was originally published by IssueWire. Read the original article here.